幾何尺寸和公差(美國戴克伊公司GD&T培訓課程)PDF文件下載

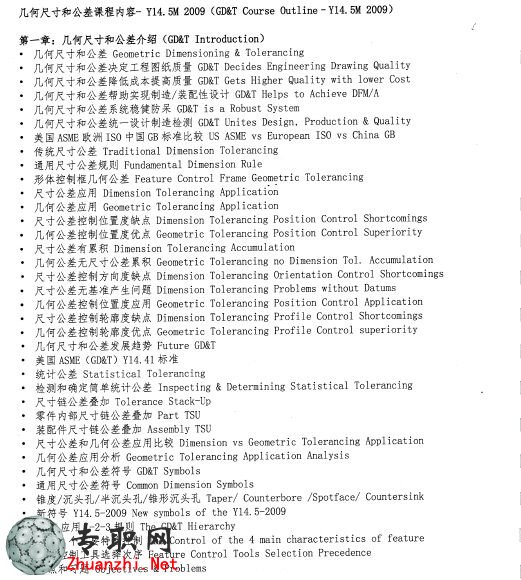

幾何尺寸和公差介紹(GMT Introduction)

幾何尺寸和公差Geometric Dimensioning&Tolerancing

幾何尺寸和公差決定工程圖紙質量GD&T Decides Engineering Drawing Quality

幾何尺寸和公差降低成本提高質量GD&T Gets Higher Quality with lower Cost

幾何尺寸和公差幫助實現制造/裝配性設計GD&T Helps to Achieve DFM/A

幾何尺寸和公差系統穩健防呆GD&T is a Robust System

幾何尺寸和公差統一設計制造檢測GD&T Unites Design, Production&Quality

美國ASME歐洲ISO中國GB標準比較US ASME vs European ISO vs China GB

傳統尺寸公差Traditional Dimension Tolerancing

通用尺寸公差規則Fundamental Dimension Rule

形體控制框幾何公差Feature Control Frame Geometric Tolerancing

尺寸公差應用Dimension Tolerancing Application

幾何公差應用Geometric Tolerancing Application

尺寸公差控制位置度缺點Dimension Tolerancing Position Control Shortcoming

幾何公差控制位置度優點Geometric Tolerancing Position Control Superiority

尺寸公差有累積Dimension Tolerancing Accumulation

A何公差無尺寸公差累積Geometric Tolerancing no Dimension Tol. Accumulation

尺寸公差控制方向度缺點Dimension Tolerancing Orientation Control Shortcoming

尺寸公差無基準產生I’g題Dimension Tolerancing Problems without Datums

幾何公差控制位置度應用Geometric Tolerancing Position Control Application

尺寸公差控制輪廓度缺點Dimension Tolerancing Profile Control Shortcoming

幾何公差控制輪廓度優點Geometric Tolerancing Profile Control superiority

幾何尺寸和公差發展趨勢Future GD&T

美國ASME (GD&T) Y14.41標準

統計公差Statistical Tolerancing

檢測和確定簡單統計公差Inspecting & Determining Statistical Tolerancing

尺寸鏈公差疊加Tolerance Stack-Up

零件內部尺寸鏈公差疊加Part TSU

裝配件尺寸鏈公差疊加Assemb珍TSU

尺寸公差和幾何公差應用比較Dimension vs Geometric Tolerancing Application

JL何公差應用分析Geometric Tolerancing Application Analysis

幾何尺寸和公差符號GD&T Symbols

通用尺寸公差符號Common Dimension Symbols

錐度/沉頭孔/半沉頭孔/錐形沉頭孔Taper/ Counterbore /Spotface/ Countersink

新符號Y14.5-2009 New symbols of the Y14.5-2009

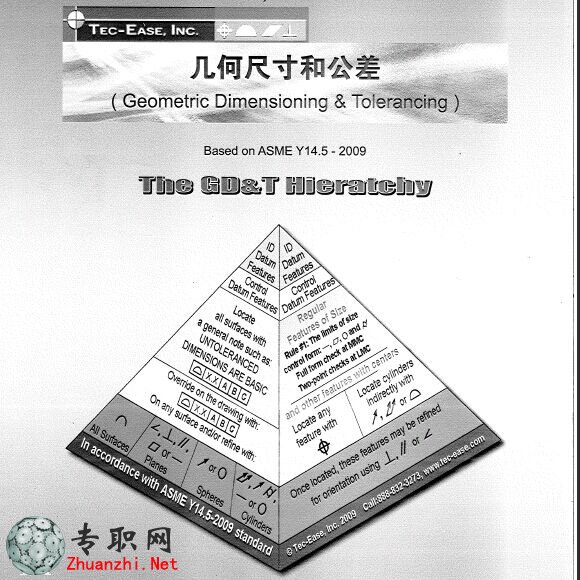

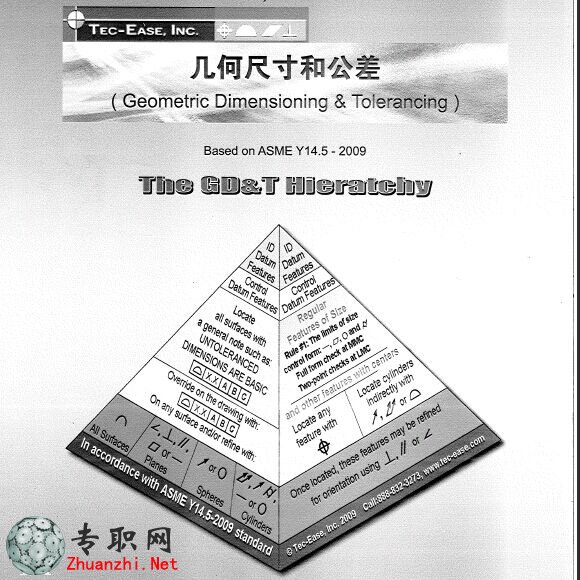

幾何尺寸和公差應用1-2-3規則The GD&T Hierarchy

形體4個主要特性控制The Control of the 4 main characteristics of feature

形體控制工具選擇次序Feature Control Tools Selection Precedence

重點和習題Objectives&Problems

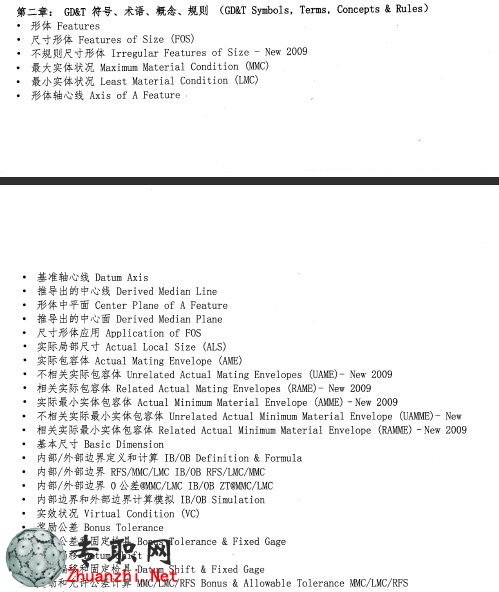

幾何尺寸和公差介紹(GMT Introduction)

幾何尺寸和公差Geometric Dimensioning&Tolerancing

幾何尺寸和公差決定工程圖紙質量GD&T Decides Engineering Drawing Quality

幾何尺寸和公差降低成本提高質量GD&T Gets Higher Quality with lower Cost

幾何尺寸和公差幫助實現制造/裝配性設計GD&T Helps to Achieve DFM/A

幾何尺寸和公差系統穩健防呆GD&T is a Robust System

幾何尺寸和公差統一設計制造檢測GD&T Unites Design, Production&Quality

美國ASME歐洲ISO中國GB標準比較US ASME vs European ISO vs China GB

傳統尺寸公差Traditional Dimension Tolerancing

通用尺寸公差規則Fundamental Dimension Rule

形體控制框幾何公差Feature Control Frame Geometric Tolerancing

尺寸公差應用Dimension Tolerancing Application

幾何公差應用Geometric Tolerancing Application

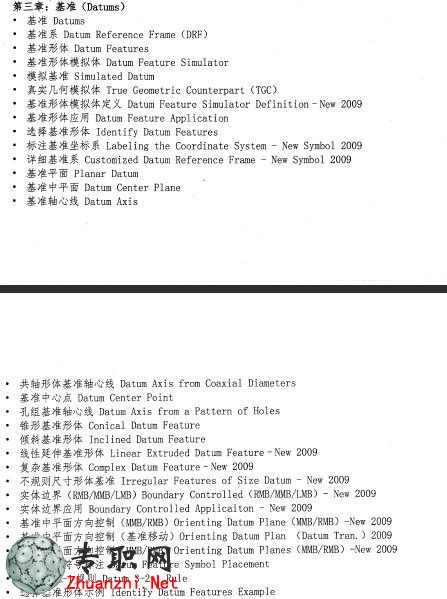

尺寸公差控制位置度缺點Dimension Tolerancing Position Control Shortcoming

幾何公差控制位置度優點Geometric Tolerancing Position Control Superiority

尺寸公差有累積Dimension Tolerancing Accumulation

A何公差無尺寸公差累積Geometric Tolerancing no Dimension Tol. Accumulation

尺寸公差控制方向度缺點Dimension Tolerancing Orientation Control Shortcoming

尺寸公差無基準產生I’g題Dimension Tolerancing Problems without Datums

幾何公差控制位置度應用Geometric Tolerancing Position Control Application

尺寸公差控制輪廓度缺點Dimension Tolerancing Profile Control Shortcoming

幾何公差控制輪廓度優點Geometric Tolerancing Profile Control superiority

幾何尺寸和公差發展趨勢Future GD&T

美國ASME (GD&T) Y14.41標準

統計公差Statistical Tolerancing

檢測和確定簡單統計公差Inspecting & Determining Statistical Tolerancing

尺寸鏈公差疊加Tolerance Stack-Up

零件內部尺寸鏈公差疊加Part TSU

裝配件尺寸鏈公差疊加Assemb珍TSU

尺寸公差和幾何公差應用比較Dimension vs Geometric Tolerancing Application

JL何公差應用分析Geometric Tolerancing Application Analysis

幾何尺寸和公差符號GD&T Symbols

通用尺寸公差符號Common Dimension Symbols

錐度/沉頭孔/半沉頭孔/錐形沉頭孔Taper/ Counterbore /Spotface/ Countersink

新符號Y14.5-2009 New symbols of the Y14.5-2009

幾何尺寸和公差應用1-2-3規則The GD&T Hierarchy

形體4個主要特性控制The Control of the 4 main characteristics of feature

形體控制工具選擇次序Feature Control Tools Selection Precedence

重點和習題Objectives&Problems

非標自動化循環洗刷除污3C清洗機

非標自動化循環洗刷除污3C清洗機3D模

非標自動化循環洗刷除污3C清洗機

非標自動化循環洗刷除污3C清洗機3D模

非標導向銷自動上料機構工程圖+B

非標導向銷自動上料機構工程圖+BOM+3

非標導向銷自動上料機構工程圖+B

非標導向銷自動上料機構工程圖+BOM+3

9軸平面伺服高速焊耳帶機口罩機

9軸平面伺服高速焊耳帶機口罩機全套3

9軸平面伺服高速焊耳帶機口罩機

9軸平面伺服高速焊耳帶機口罩機全套3

自動化桌面式覆膜機3D模型圖紙_S

自動化桌面式覆膜機3D模型圖紙_Solid

自動化桌面式覆膜機3D模型圖紙_S

自動化桌面式覆膜機3D模型圖紙_Solid

雙工位左右滾筒式AGV小車3D模型_

雙工位左右滾筒式AGV小車3D模型_Soli

雙工位左右滾筒式AGV小車3D模型_

雙工位左右滾筒式AGV小車3D模型_Soli

按壓測試機(含彈性機構)3D模型

按壓測試機(含彈性機構)3D模型_Sol

按壓測試機(含彈性機構)3D模型

按壓測試機(含彈性機構)3D模型_Sol

紗筒轉運車RGV小車3D模型圖紙_So

紗筒轉運車RGV小車3D模型圖紙_SolidW

紗筒轉運車RGV小車3D模型圖紙_So

紗筒轉運車RGV小車3D模型圖紙_SolidW